How to speed up the products with less time in flow wrapper

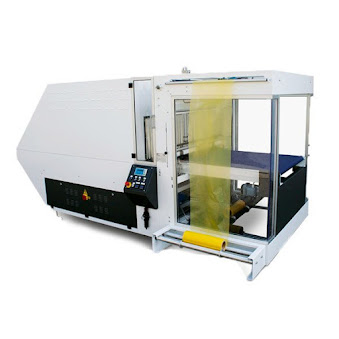

Flow-wrapped products, which are widely used in daily life, are over saturated in the market. The goods can be wrapped regardless of their size, shape, or feature. Common uses include those for dry fruit, baked goods, pharmaceuticals, everyday items, tools, games, sweets, and scratch cards. The fundamental draw of flow packaging equipment is its adaptability. The Net linear scales are horizontal flow wrapper encases the product in film, extending its shelf life and guarding against external contamination, wear, and damage. Money is time. Saving time and money is possible with a high speed flow packing machine. The automated system replaces manual packaging as a packaging method. A variety of items can be wrapped with high efficiency using flow-wrap technology, which can pack up to 300 bags per minute. Consumers purchase products for a variety of reasons, including if the goods are appealing enough to capture attention. To accentuate the brand, printed flow-wrap packaging comes in a var